how to do rockwell hardness test|rockwell hardness test theory : Brand The Rockwell Hardness Test uses a diamond cone or hardened steel ball to indent the material being tested. Each time a test is performed, two loads are applied to the sample. First, the indenter is forced into the test material under .

WEBNếu disable Googlelight bằng cách dùng cấu hình HTTP mà Google gợi ý, các kết quả hiển thị từ Google sẽ có kèm thêm một thông báo "Slow to load" , nếu để light, trang web sẽ dừng hoạt động, chúng tôi cảm thấy lỗi đó chỉ dành cho những trang

{plog:ftitle_list}

web| Poki. 冒险游戏. 生存游戏 密室逃脱游戏 僵尸游戏 点并单击游戏. 动作游戏 平台游戏. 游戏. 冒险游戏. 最好的在线免费冒险游戏有哪些? Sword Masters. Lurkers.io. Tribals.io. Gold Digger FRVR. Lands of Blight. Vectaria.io. Blocky Universe. Pixel Realms. Level Devil. We Become What We Behold. 最受欢迎的手机或平板冒险游戏有哪些? Sword Masters. .

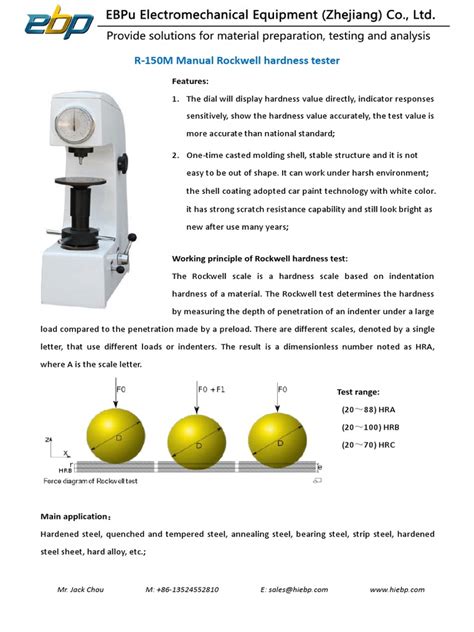

The Rockwell hardness scale is designed to determine the hardness of materials like aluminum, thin steel, lead, iron, titanium, copper alloys, and cemented carbides. This article explains the procedure to perform the Rockwell hardness .Learn more about hardness testing basics here. The Rockwell hardness test method, as defined in ASTM E-18, is the most commonly used hardness test method. You should obtain a copy of this standard, read and understand the . The Rockwell hardness test is the industry standard measuring system used to determine how resistant a material is to another object. Hardness is defined as a material’s resistance to permanent indentation.

What is the Rockwell Hardness Test? Rockwell Hardness Test Procedure: A Step-by-Step Guide. How Does the Rockwell Hardness Test Work? How to Use a Rockwell Hardness Tester? Interpreting the Results with a Rockwell Hardness .

The Rockwell hardness test method is a simple process that uses a diamond cone with a round tip for harder materials and a hardened steel ball indenter for softer ones. With every test, two loads are applied to the test subject.The Rockwell Hardness Test uses a diamond cone or hardened steel ball to indent the material being tested. Each time a test is performed, two loads are applied to the sample. First, the indenter is forced into the test material under . Tutorial video on how to use rockwell hardness tester.For Scale B Tests.

Basic principle and practical procedure of the Rockwell hardness test - Testing machine, test piece, conical diamond indenter - Basic principle, hardness definition, testing procedure.Learn all you need to know about Rockwell hardness testing – including test definitions, test calculations and insight into Rockwell hardness testing machines and HRC hardness testers – with knowledge and expertise from .See also: Hardness. Rockwell Hardness Test. Rockwell hardness test is one of the most common indentation hardness tests, that has been developed for hardness testing. In contrast to Brinell test, the Rockwell tester measures the depth of penetration of an indenter under a large load (major load) compared to the penetration made by a preload .ACKNOWLEDGMENTS Theauthorwouldliketothankthefollowingpersonsforsharingtheir experienceandprovidinginformationforthisGuide.Theirinputandreview .

In the Rockwell hardness test, a differential-depth method, the residual depth of the indent made by the indenter, is measured.In contrast, the size of the indentation is measured in the Brinell, Vickers and Knoop optical test .

rockwell hardness testing chart

The concept of the Rockwell Hardness test is essentially similar to its counterparts. A sample material is fed on to either a digital or manual Rockwell hardness tester which would then drop a set load ending with an indenter on the surface. Then, the strength of the material will be determined by the nature of the indentation left on the sample.High Rockwell hardness numbers represent hard materials and low numbers soft materials. d 2 www.wilsoninstruments.com Fundamentals of Rockwell Hardness Testing Like the Brinell, Vickers, Knoop, Scleroscope and Leeb tests - all of which fall in the general category of indentation hardness tests - the Rockwell test is a measure of the

potato moisture meter

Rockwell Hardness Test. The Rockwell hardness test evaluates the hardness of a material by measuring the permanent depth of indentation due to an applied concentrated load. The higher the number on the Rockwell hardness scale, the harder the material. The test is conducted by applying a minor force of 10 Kg using a diamond cone or a steel ball .The Rockwell hardness test method, as defined in ASTM E-18, is the most commonly used hardness test method. The Rockwell test is generally easier to perform and more accurate than other hardness methods. The Rockwell test method is used on all metals except in circumstances where the test metal structure or surface condition would introduce too . In the Rockwell hardness test, an indenter is pressed into the material to be tested. The indentation depth serves as a measure of the hardness! The measuring process of the Rockwell test is carried out in three steps. First, the indenter is placed on the surface to be tested with a so-called preload F 0 of 98 N. In this way, the influences of .

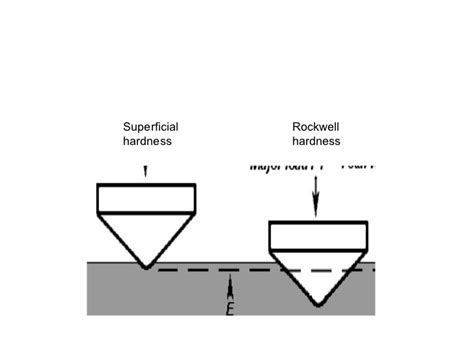

Types of Rockwell Hardness Test. The Rockwell hardness test is categorized into three types: Regular Rockwell hardness test: In this test, a load of 60, 100, or 150 kg is applied to the surface of the material for a few seconds, depending on the hardness of the material.Hardness testing within the realm of materials testing. Today, hardness testing is one of the most widely used methods in mechanical materials testing, especially for metals. On the one hand, this test method can be used to find qualitative relations to other material properties (e.g., strength, stiffness, density) or to the material behavior under certain stresses (e.g., abrasion . The most common hardness tests are explained below: Rockwell: Developed to give a quick reading, mainly for metallic samples. The depth of the deformation made by the indenter is measured, and a deeper indentation is assigned a lower number, indicating a softer material. Two broad types of tests are used: the Rockwell superficial hardness and .

rockwell hardness tester diagram

Figure 23.4 Schematic of the Rockwell indentation process using a diamond brale Indenter. The Rockwell hardness test is based on the measurement of the depth to which an indenter is forced by a heavy (major) load beyond the depth resulting from a previously applied preliminary (minor) load. The test follows the sequence, see Figure 23.4 to your .The Rockwell hardness test method is a simple process that uses a diamond cone with a round tip for harder materials and a hardened steel ball indenter for softer ones. With every test, two loads are applied to the test subject. First, an indenter is forced into the test subject under an initial load of 10kg-f, and the depth is recorded.

Minimum Thicknesses for the Rockwell Hardness Test. Since the Rockwell test needs to make an indent in the test piece, there’s a minimum thickness associated with the test. If the material is too thin, you’ll be measuring the hardness of the supporting anvil more so than the test piece. Here’s a little chart on the minimum material . The Rockwell hardness test is the industry standard measuring system used to determine how resistant a material is to another object. Hardness is defined as a material’s resistance to permanent indentation. This test was .

🕑 Reading time: 1 minute Hardness of a material is defined as its resistance to indentation. Rockwell hardness test measures the permanent depth of indentation on a metal by applying a fixed load using an indenter. The smaller the indentation value, the harder is the material. The Rockwell hardness scale is designed to determine the [.]

3.2 Conducting the Test. Positioning the Sample: Secure the material sample in the testing machine.; Selecting the Indenter: Choose the appropriate ball diameter based on the material hardness.; Applying the Load: Gradually apply the .Hardness Conversion for Rockwell C Scale or High Hardness Range . Regular Rockwell Testing. In this test method, the minor (preload) is always 10 kgf. The major load may be any of the following loads: 60 kgf, 100 kgf, or 150 kgf. Superficial Rockwell Testing.

Conducting a hardness test using the Rockwell hardness method can be difficult, especially if you misunderstand its principles and application. Not to overstate it, but without an understanding of the Rockwell hardness method, you might end up going round in circles or, worse still, end up with an inaccurate material hardness value. Hardness generally refers to the resistance of a material to scratching or indentation, and a qualitative measure of the strength of the material. The most commonly used hardness tests are the Rockwell test, Brinell test and the Vickers hardness test. This article will provide an introduction into durometer hardness and the gauge used to .

The Rockwell hardness test involves making an indentation on the test material. The indenter is either a conical diamond or a steel ball. Indenter ball diameters range from 1/16 to 1/2 inches and are chosen based on the test parameters. .

rockwell hardness test theory

Rockwell Hardness. This method tests the hardness of steel parts by applying loads to parts via either a tungsten carbide ball or a spheroconical diamond indenter. A part’s testing surface and seating surface must be properly prepared prior to testing. Inadequate surface preparation can lead to failed tests or false readings.The Rockwell hardness test is an empirical indentation hardness test that can provide useful information about metallic materials. This information may correlate to tensile strength, wear resistance, ductility, and other physical characteristics of metallic materials, and may be useful in quality control and selection of materials. .

Many Rockwell test standards also stated that while processing the test, there should be a distance of more than 2.5 times the diameter of the indentation between mid of an indentation and the periphery of the material. Thickness of Test Material In the Rockwell hardness test, indentation depth depends on the thickness of the material. The first step that I always take when performing Rockwell hardness test is choosing either diamond cone indenter or hard steel ball depending on material which I want to test. The next thing that I do prior to this process involves putting the specimen on the anvils of testing machine and making contact with indenter with its surface .

The Rockwell hardness test. Rockwell is a fast hardness test method developed for production control, with a direct readout, mainly used for metallic materials. The Rockwell hardness (HR) is calculated by measuring the depth of an indent after an indenter has been forced into the specimen material at a given load.

A must for most any machine shop! An easy-to-use, dramatically less expensive alternative to a Benchtop Hardness Tester, the TTC Hardness Tester File Set allows you to quickly ascertain the hardness of your material. Watch resident tech expert Kurt Repsher demonstrate how to use Rockwell Hardness Tester Files in this video, and subscribe to our channel to see more .

potted plant dry on tope moisture meter says moist

potting soil moisture meter

Resultado da The Great: Created by Tony McNamara. With Elle Fanning, Phoebe Fox, Gwilym Lee, Adam Godley. A royal woman living in rural Russia during the 18th century is forced to choose between her own personal happiness and the future of Russia, when she marries an Emperor.

how to do rockwell hardness test|rockwell hardness test theory